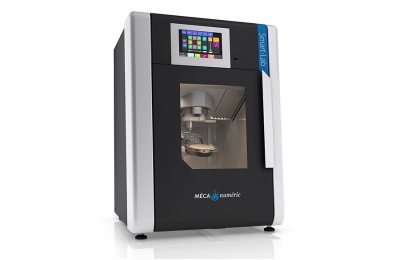

SMART-LAB

Our Smart-Lab solution has been designed for intensive and accurate machining of plastic composite resins, electronic samples, brass or aluminum pieces, PPMA parts.

- Description

- Technical datas

Thanks to its built-in compressor, SMART-LAB requires only an electrical socket to operate. It can be placed on its technical cabinet, which includes a silent cyclonic suction system for greater manoeuvrability.

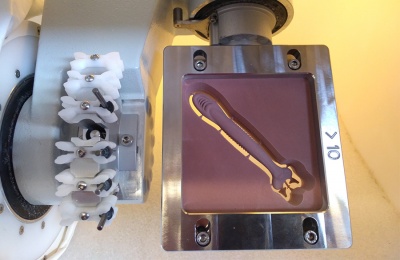

This versatile machine can easily machine a wide range of materials in 4 and 5 axes, wet or dry: aluminium, brass, composite resins, PMMA, WAX, etc.

It is also compatible with any computer-aided manufacturing system that delivers NC code.

HIGHLIGHTS :

- 4 and 5-axis machining of soft materials and metals: aluminium, brass, etc.

- Open to all CAM software.

- Small footprint thanks to original choice of kinematics.

- Precision thanks to high-quality kinematics: ball screws and ground rails.

- Powerful 500W - 60,000rpm spindle and brushless servomotors.

- Simplicity thanks to its colour touch screen

- Autonomous thanks to its integrated compressor

- The know-how of Mécanuméric's design, manufacturing and after-sales teams.

- Tool diameters from 3 to 0.5 mm.

- Standard consumables format.

| SMART-LAB | |

| Number of axis | 5 |

| Angular maximum for the rotary axis | 4 : +- 30° / 5 : 0 > 180° |

| Brushless motors | √ |

| Spindle 500W at 60000 tr/min | √ |

| Automatic tool changing system | √ |

| Number of tools in changer | 12 |

| Tooling measurement system | √ |

| Tooling breaking sensors | √ |

| Tooling wearing sensors | √ |

| Water cooling | √ |

| Dimensions L x P x H when door closed - mm | |

| Weight in kg | 100 |

| Com Ports | 1 USB + 1 Ethernet |

| Electrical Tension | 230 VAC 50/60 Hz |