DENTAL

As a supplier of industrial equipment, MECANUMERIC offers the design and manufacture of software and machines specialising in CNC milling and CNC machining for professionals in the dental world such as prosthetists and dentists.

One of the many advantages of MECANUMERIC's CNC software and machines is its ability to meet all the specific demands in the dental field on which patient satisfaction depends. Whatever the type of manufacturing, the characteristics of the material used, the shapes and dimensions of the parts to be machined and milled, their need for a perfect finish, the wide range of CAD software and machining machines of the CHARLYDENTAL series will bring you a solution adapted to all your needs.

Tailor-made solutions for dental prosthesis manufacturers

MECANUMERIC solutions are suitable for the unitary manufacturing of dental prostheses by a dentist in the office as well as for intensive manufacturing in the laboratory. Whatever type of prosthesis you need to machine to restore the patient's smile, our team dedicated to dental professionals is at your disposal and provides you with the solution to your needs.

Our customer service and our hotline support you throughout the use of your machine, provide after-sales service and maintenance as well as the supply of spare parts and consumables.

Powerful software for the manufacture of many dental prostheses

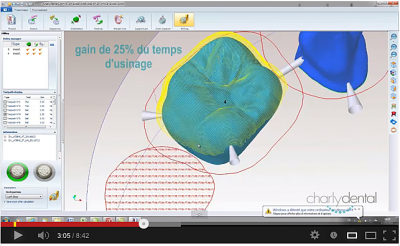

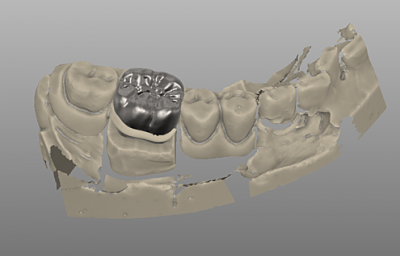

The evolution of technologies allows the design of many solutions through the use of CAD software. Easy to use, the CAD software “adjoining prosthesis” or “fixed prosthesis” makes it possible to reduce the time necessary for the machining of the parts and therefore to obtain control of the manufacturing costs of unit prostheses and intensive manufacturing in the dental laboratory.

The manufacturing operations are programmed on a computer and the software controls the CNC machine (3, 4 or 5 axis milling machine and the milling machine) throughout the process and the machining and milling operations.

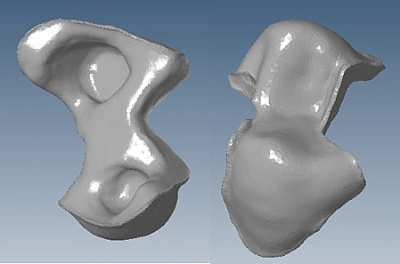

The CAD software can create a prototype, program the production in series of different parts and models of skeleton type prostheses or sealed, glued and screw-retained prostheses. The software controls each movement of the CNC machine taking into account the type and characteristics of the material to be machined and milled.

Each manufacturing step is carried out according to a method studied specifically for the particular needs of all types of achievements in the dental field. The “adjoined prosthesis” CAD software allows, for example, automatic undercut machining or milling of a dental prosthesis framework.

The “fixed prosthesis” CAD software enables the machining of conventional sealed frameworks, the milling of implant pillars or all types of screw-retained bars. The advanced technology contained in this software allows high quality and high precision work whatever the material used (Zyrconium oxide, Wax (wax material), composite, PMMA, CoCr or titanium)

Machines for CNC machining and milling

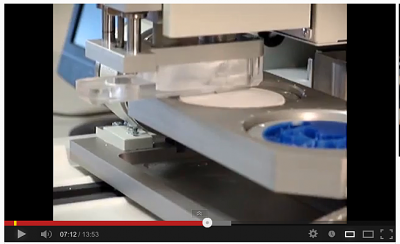

MECANUMERIC, manufacturer of industrial machines, has designed a complete range of CNC milling machines for the dental field in order to meet all the needs and constraints of manufacturing specific parts for prosthetists and dentists.

Thus, in the CHARLYDENTAL series, machining machines are designed for daily production whose simplicity of use and speed of manufacture meet the needs of dentists. Also milling machines facilitate the daily work of the dental technicians for mass production in a short time.

4-axis milling machines for the manufacture of soft and ceramic dental prostheses.

- CHARLYDENTAL CD04-S

The CHARLYDENTAL CD04-S milling machine model is designed to mill dental prostheses in 4 positioned axes. Their CAD/CAM system allows the use of the main scanners, CAD software and consumables. Compact and versatile, this CNC machine allows for the simple and fast manufacture of many components such as

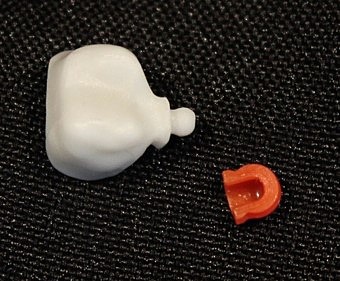

- Crowns in a lithium disilicate block,

- Rest trays,

- Orthodontic study models,

- Single frameworks (copings) and bridges.

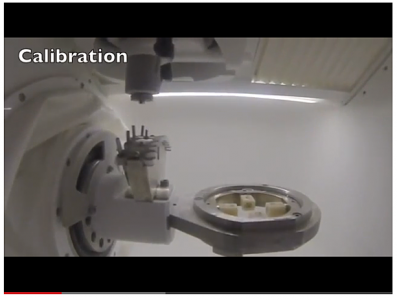

- CHARLYDENTAL CD05-S/CD05-HP

As a backup to the CHARLYDENTAL CDO4-S CNC machine, this model has 5 axes positioned to machine soft and ceramic dental prostheses, dry or with lubricated tools. Its high power reserve per spindle provides high flexibility and precision. Its 5th axis allows rotations from 0 to 180°. As simple as it is fast, it can be used to manufacture dental components such as :

- Orthodontic splints,

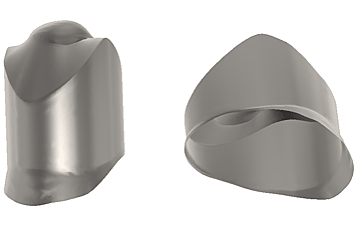

- Implant abutments with the pre-milled technique,

- Screwed bars,

- Dental models.

- CHARLYDENTAL MICROLAB 4+

The touch screen of the CHARLYDENTAL MICROLAB 4+ simplifies the daily work of dentists and dental technicians. High-performance, durable and compatible with a wide range of software, this industrial CNC machine guarantees perfectly finished milling of various dental components such as :

- Single crowns,

- Telescopic crowns,

- Temporary crowns and bridges,

- Core and onlay inlays.

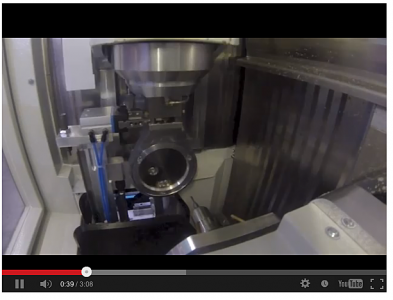

- CHARLYDENTAL CD 50

MECANUMERIC, an industrial equipment company, offers prosthetists and dentists the CHARLYDENTAL CD 50 CNC machine. This high-end digital milling machine with 5 simultaneous axes allows the intensive machining and grinding of soft or hard materials as well as metal (chrome-cobalt and titanium) necessary for the manufacture of numerous dental components such as :

- Bridges in different materials (WAX, Zr, PMMA...),

- Implant guides,

- Skeletons in materials such as WAX, PEEK, PMMA ...,

- Veneers.