Make the best choice of pump for your waterjet cutting equipment (December, 2020)

When you want to acquire a waterjet cutting equipment, one of the essential aspects to take in account is the type of the pump to install.

On the current market there are generally two types of pumps: direct drive pumps and pumps with an intensifier.

Direct drive pumps are usually build up with 3 cylinders driven by an electric motor. When the pump is operating, those cylinders need to be cooled, most often by water circulation in an open circuit which consumes water continuously (in addition to the water which is consumed to make the cuts).

Regarding the maintenance, the necessary revision of those 3 cylinders represents a significant cost. Although the purchasing cost of a direct drive pump may be lower than a pump equipped with an intensifier, the high water consumption and maintenance costs make it an unconventional choice in the long run.

The intensifier pumps have the advantage of being built up only with 2 cylinders instead of three, which reduces maintenance costs by more than 30%.The cooling is operated by air (unit heater) or by water in a closed circuit (chiller) which does not entail any additional water consumption.

Finally, the intensifier pumps offer a major advantage: their power! Where most of the direct drive pumps offer a maximum power of 50HP and pressure up to 4000 bar, the intensifier pumps can raise up to 200HP of power and 6200 bar of working pressure, allowing you to cut your materials twice faster and also to reduce your abrasive consumption.

This wide range of power gives you the possibility of using several cutting heads simultaneously.

That is why, throughout all these years MÉCANUMÉRIC is still working in partnership with KMT, a world leader in the manufacture of pumps and heads. A partnership which allows us to propose to our customers: simple, efficient, reliable and easy-to-maintain solutions for optimal profitability.

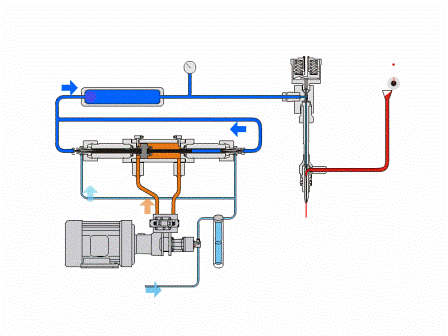

Animated diagram of a pump with an intensifier