MECAPLUS

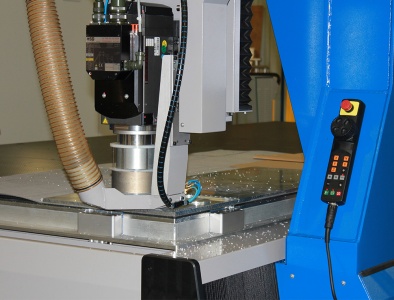

Optimized for machining aluminium, plastic materials in strong thickness and composite materials with high mechanical characteristics.

- Description

- Technical datas

- Fields of activity

Precision milling machine of simple use for machining rigid plate materials in strong thickness in the sectors of plastic, modeling, aeronautics, aluminium transformation advertising and POS or for machining 3D molds and models.

STRENGTHS

- Designed and realized for an intensive use.

- Particularly adapted for the machining of aluminium, plastic materials of strong thickness and composite materials with high mechanical properties.

- Precision milling machine, easy to operate, for the machining of rigid sheet materials of strong thickness, in the fields of plastic processing, modelling, aeronautics, aluminium processing, advertising and POP… or for the machining of moulds and 3D models.

- Equipment with fixed table – working travels 1500x3100 mm till 2500x6000 mm as standard.

- Many customization possibilities.

- Innovative and efficient vacuum tables with turbine technology or vacuum pumps.

- MECANUMERIC numerical controls as standard or SIEMENS or HEIDENHAIN type.

- Quality kinematics integrating industrial components supplied by the world leaders

Materials to be used (according to the selected spindle and tool):

- Plastic in rigid plates (PMMA-PC-PS-PVC-ABS..)

- Expanded plastic and alveolar plates

- Rigid foams (PU- PS-…)

- Semi rigid foams (KAPA line®,…)

- Composite materials for building : Alucobond®, Dibond®, Reynobond®,..

- Composite materials for industry (polyester resin loaded with glass fiber, carbone fiber...)

- Wood and by-products

- Polyester resins

- Light alloys with Aluminium or copper basis

- Steel and stainless steel

- Soft stones, marbles, granite

OPTIONS :

- Suction of milling chips by professional suction devices

- Various vacuum tables

- Rotative tool shop

- Tool coolant by oil spraying / Toool-material cooling system

- SIEMENS Numerical Control and SIEMENS servomotors

- FANUC Numerical Control and FANUC servomotors

- Automatic debatcher for holding material VILMILL®

- Multi-heads system (2, 3 or 4 heads) for simultaneous machining of several parts

- Overall protection enclosure

- System of automatic loading unloading by cross bar or interchangeable tables.

TECHNICAL DESCRIPTION :

- Structure with fix table and mobile gantry

- Frame single block in welded steel

- High inertia welded moving gantry

- Vacuum table in aluminium profiles or composite

- Holding of plates by vacuum generated either by side channel blowers, or by claw vacuum pumps

- Motorization: AC Brushless servomotors on 4 axes (X1-X2-Y-Z), double driving on X axis (motor power from 1 to 2 Kw according to CN used. Selection of the zones by manual valves

- Transmission: high precision ball screws on all axes (diameter 40 mm or 63 mm)

- Guidance: grinded steel rails size 35 and preloaded ball bearings

- Numerical control POWER AUTOMATION MECANUMERIC CN7100 with 15 inches touch screen, hardware integrated, Data input by Ethernet link, USB port, import of ISO code files (option SIEMENS 840 or FANUC 16 O)

- Numerous electrospindles available

PERFORMANCE :

- Maximum speed : 600 mm/sec

- Acceleration : 1 ms²

- Repeatability : +/-0.02 mm

- Resolution : 0.001 mm

DIMENSIONS :

| MPL3115 | MPL3121 | MPL4121 | MPL6121 | |

| X stroke | 3110 | 3110 | 4100 | 6100 |

| Y stroke | 1560 | 2100 | 2100 | 2100 |

| Z stroke (standard / option) | 275/500 | 275/500 | 275/500 | 275/500 |

| Maximum material width | 1750 | 2300 | 2300 | 2300 |

| Passage under gantry (standard / option) | 375/600 | 375/600 | 375/600 | 375/600 |

| Width | 4650 | 4650 | 5650 | 7650 |

| Depth | 3200 | 3600 | 3600 | 3600 |

| Height | 3160 |

3160 |

3160 | 3160 |

|

Weight |

5800 | 7000 | 8000 | 11000 |

Building façades

Lights

Furniture

Wooden low-relief

Satellites

Ceramics

Cases and boxes

Rapid prototyping

Bathroom elements

Structure parts and tooling

Technical plastic parts

Boat rudder blade machining

Parts for racing motorcycles

Parts for the train industry

Kitchen elements

Formworks

Gutterings

Weather vanes

Plastics and PVC frames

Aluminium frames

Household appliances

Aeronautic seats

Aircraft interior furnishing

Side windows

Trolleys

Bus parts

Parts for trams

Parts for subways

Trucks parts

Electric vehicles parts

Plastics machining

Moulds and models

[TESTIMONIAL] Franck RENDA - President EUROTECH-RENDA EUROTECH RENDA (Refractory Materials)

EUROTECH-RENDA specialises in materials for industrial thermal insulation.

[TESTIMONIAL] Fabrice TREGOU - EMPREINTE (Signage)

Empreinte designs and manufactures custom signage in a wide range of sectors.

Machining new materials in the aerospace industry: MÉCANUMÉRIC, expertise at the service of innovation

Advantages, issues and machining problems: composites offer significant advantages in the aeronautical sector, but what are the challenges to be met in order to benefit from them?

![[TESTIMONIAL] Franck RENDA - President EUROTECH-RENDA EUROTECH RENDA (Refractory Materials)](/medias/articles/vignettes/eurotech-renda_1.jpg)

![[TESTIMONIAL] Fabrice TREGOU - EMPREINTE (Signage)](/medias/articles/vignettes/empreinte_2.jpg)