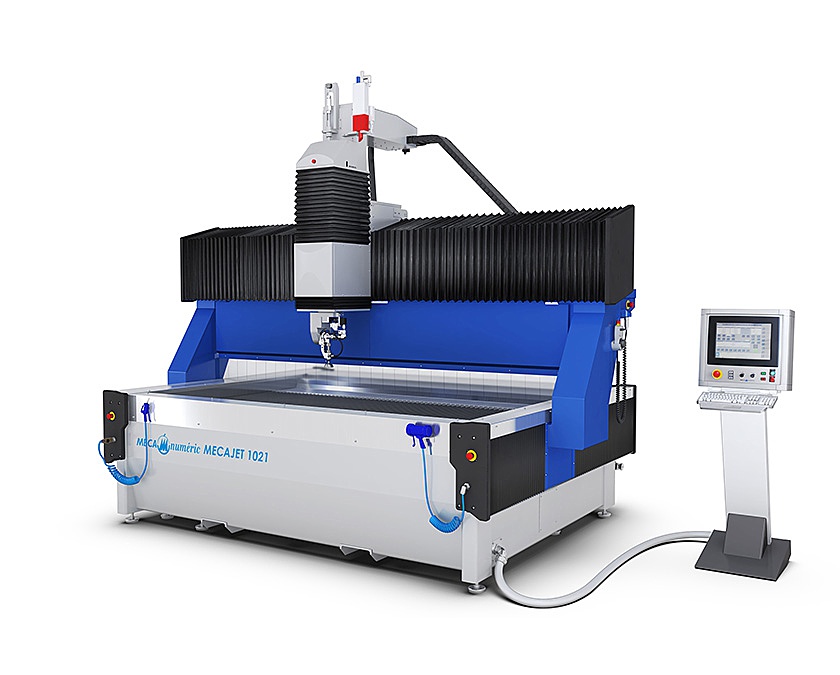

MECAJET II

Discover MECAJET II the new range of Water Jet equipments conceived by MECANUMERIC, machining and cutting by VHP soft materials, and, with addition of abrasive, hard materials.

Composite cutting with MECAJETII

- Description

- Technical datas

- Fields of activity

Discover the new range of very high pressure Waterjet equipment MECAJET II designed and manufactured by MECANUMERIC, for cutting of several materials:

* Soft materials:

- rubber

- plastics

- leathers...

* And, with addition of abrasive, hard materials:

- metal

- ceramic

- glass

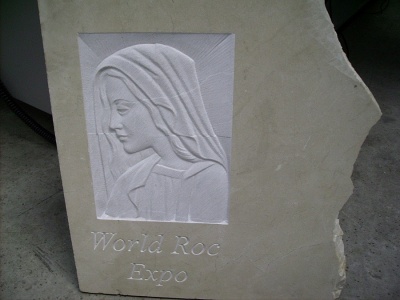

- stone

- composite materials...

STRENGTHS

- Designed and manufactured for intensive and professional use.

- Cutting of soft materials with pure water (rubber, plastics, foam, leather…) and hard materials (metal, ceramic, glass, stone, composites...) with addition of abrasive.

- Fixed table equipment with working size from 1000x2000 mm up to 2000x6000 mm in standard.

- Wide possibilities of customization.

- Driving system on numerical control CN9000 ISO and CAM software dedicated for water jet cutting applications.

- High pressure pumps at 4136 bar or 6200 bar.

- Patented cutting heads and systems of metering and feeding abrasive.

- 3 axis or continuous 5 axis cutting heads.

- Quality kinematics which integrates industrial components delivered by worldwide leaders in their sector and assembled on high inertia steel welded frame, stainless steel tank with adjustable water level.

OPTIONS

- 5 axis head for mounting on Z axis single head machines

- Additionnal 3 axis head for mounting on Z axis double head machines

- Divider, fourth horizontal digital axis for work on tubes

- Manual head orientation system +/- 45 ° angle

- Electronic flatness tracking system for 3-axis Z1 single head

- Auxiliary head for drilling - Electrospindle 2.2 KW / 15,000 rpm max

- Auxiliary drilling head, pneumatic

- Water softener

- Ballast system for rapid immersion

- Sludge suction and recovery system

- Aiming laser

- Abrasive water check valve

STRUCTURE

- high inertia steel welded structure cast in one piece,

- welded steel mobile gantry, stainless steel tank,

- table with zinc coated for abrasive cutting, or plastic honeycomb coating for cutting with pure water.

KINEMATICS

- guidance by grinded steel rails and preloaded ball bearings,

- transmission by ballscrews on XYZ axes,

- motorisation: « AC Brushless » servomotors.

| MECAJET II 1021 | MECAJET II 1531 | MECAJET II 2041 | ||||

| 3 axes | 5 axes | 3 axes | 5 axes | 3 axes | 5 axes | |

| X stroke | 2500 | 2100 | 3500 | 3100 | 4500 | 4100 |

| Y stroke | 1320 | 1100 | 1820 | 1520 | 2220 | 1760 |

| Z stroke | 300 | 300 | 300 | 300 | 300 | 300 |

| Maximum sheets dimensions in the tank in mm | 1340 x 2600 | 1840 x 3600 | 4520 x 2240 | |||

| Distance gantry / table in mm | 450 | 450 | 450 | |||

| Max. speed in m/min : pure water / abrasive | 25 | 25 | 25 | |||

| Overall lenght in mm | 2800 | 3300 | 3500 | |||

| Overall width in mm | 3800 | 4800 | 5750 | |||

| Height in mm (workshop / transport) | 4000/2800 | 4000/2800 | 5400/2800 | |||

| Weight in kg (empty tank) | 4000 | 5500 | 7000 | |||

| CUTTING HEADS | ||||||

| Pure water cutting head KMT AQUALINE | ||||||

| Abrasive cutting head KMT AUTOLINE or IDE | ||||||

| Abrasive tank under pressure, capacity of 200 or 1000 liters, KMT ABRALINE | ||||||

| ENERGY | ||||||

| 6 bars – 3 at 8 m3/h | ||||||

| 400 V 3-phase 50 Hz + earth 50 to 150 A per phase according pump | ||||||

| THP PUMPS | ||||||

| KMT | ||||||

| Type | SL-V 15S | SL-VI 30S | SL-VI 50S | SL-VI 100S | PRO-I 60SS | PRO-I 125D |

| Power | 15 HP | 30 HP | 50 HP | 100 HP | 60 HP | 125 HP |

| Max. Pressure | 3800 | 4136 | 4136 | 4136 | 6200 | 6200 |

| BFT | ||||||

| Type | ECOTRON 40.22 | ECOTRON 40.37 | ECOTRON 40.45 | SERVOTRON 40.45 | HYPERTRON 60.45 | |

| Power | 30 HP | 50 HP | 60 HP | 60 HP | 60 HP | |

| Max. Pressure | 4000 | 4000 | 4000 | 4000 | 6000 | |

Bag / Wallet

Leather furniture

Building façades

Lights

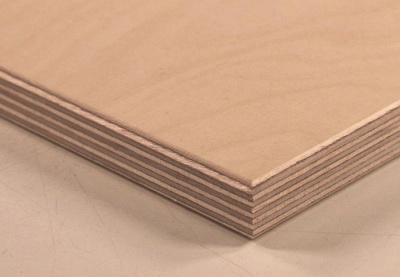

Furniture

Marquetry

Satellites

Wood cutting for marquetry

Decorative friezes

Ceramics

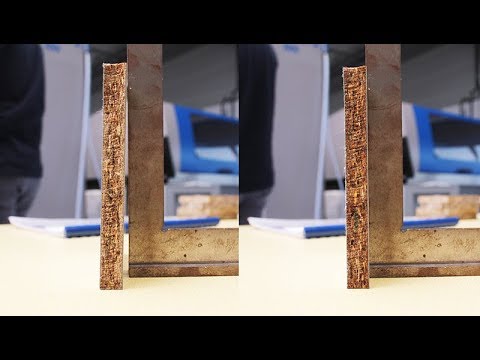

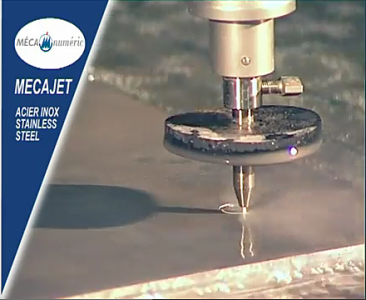

Water jet cutting

Waterjet cutting stainless steel

Shoes

Funeral marking

Bathroom elements

Structure parts and tooling

Boat rudder blade machining

Parts for racing motorcycles

Parts for the train industry

Windows

Kitchen elements

Formworks

Gutterings

Weather vanes

Aluminium frames

Household appliances

Aircraft interior furnishing

Trolleys

Airbag elements

Bus parts

Parts for trams

Parts for subways

Electric vehicles parts

Precision engineering technical parts

Machining new materials in the aerospace industry: MÉCANUMÉRIC, expertise at the service of innovation

Advantages, issues and machining problems: composites offer significant advantages in the aeronautical sector, but what are the challenges to be met in order to benefit from them?

[TESTIMONIAL] SIAN S.N.C. - Engraving and visual communication

The company operates in various sectors, ranging from furniture to the shipbuilding and automotive industry, to the protection of works of art.

[TESTIMONIAL] Franck RENDA - President EUROTECH-RENDA EUROTECH RENDA (Refractory Materials)

EUROTECH-RENDA specialises in materials for industrial thermal insulation.

![[TESTIMONIAL] SIAN S.N.C. - Engraving and visual communication](/medias/articles/vignettes/logo-sian-snc_1_1.jpg)

![[TESTIMONIAL] Franck RENDA - President EUROTECH-RENDA EUROTECH RENDA (Refractory Materials)](/medias/articles/vignettes/eurotech-renda_1.jpg)