Waterjet cutting with abrasives

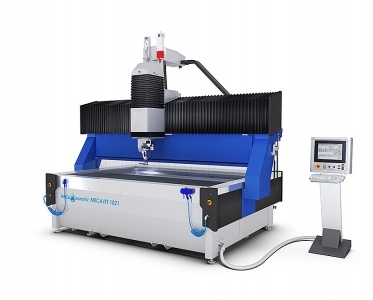

Waterjet cutting can be used to cut a wide range of metals. It represents an interesting alternative to laser and plasma techniques. It is both more precise and less expensive. Table-top cutting technology enables thicker metals such as titanium and aluminium to be cut.

With this cold cutting process, no deformation can be produced by the heat, and there is no hardening of the material. Its precision eliminates the need for most of the retouching routinely carried out in other processes. Finally, water jet cutting enables thicker metals to be cut with great precision.

The addition of abrasive, the absence of vibration and the thermal neutrality of the operation mean that glass can be cut in a variety of shapes and patterns. Simple techniques will prevent the glass from cracking. This makes most glass cuts possible and more economical.

High-pressure water jet technology can also be used to cut many other materials: stainless steel, alloys, stone, ceramics, tiles, foam, rubber, fabrics, cardboard, etc.